×

×

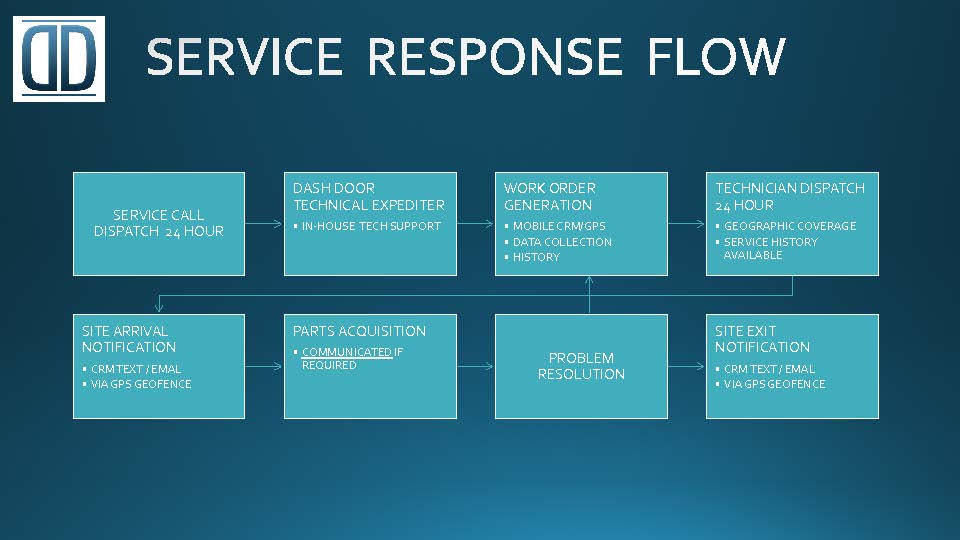

Service Response Work-Flow Many lessons have been learned over decades of providing service to and interacting with facility managers. Perhaps the easiest step which will minimize frustration by all parties is to clearly define the service call work-flow. IT IS IMPORTANT that a facility’s service vendors make clear and COMMUNICATE their preferred service response work-flow; this […]

See PostCarrying out safety inspections of automatic doors is not a difficult procedure. A few minutes are all that is needed to make sure that the doors installed at your property are completely functional. The following is how safety inspections are carried out.

See Post